|

| Circular Polarized Feed |

- True circular polarity

Competitors' designs have no circular polarity

at all. They use just standard, rectangular

waveguides that have no added rotation.

- No moving parts

- Reduced reflection

The lowest measured power reflection of any

feed in the industry, providing reduced cooling

costs and improved heat delivery.

- No frequency dependence

Feed reacts uniformly to various signals, reducing

the power reflection and high peak voltage

patterns that exist with other polarized and rotary

feeds.

- Improved tuning

Produces uniform electric fields and reduces

the peak voltages that cause uniformity issues,

arcing and half-cooked bacon strips.

- Reduces arcing & burning

- Lower maintenance costs

Produces uniform electric fields and reduces

the peak voltages that cause uniformity issues,

arcing and half-cooked bacon strips.

|

|

|

|

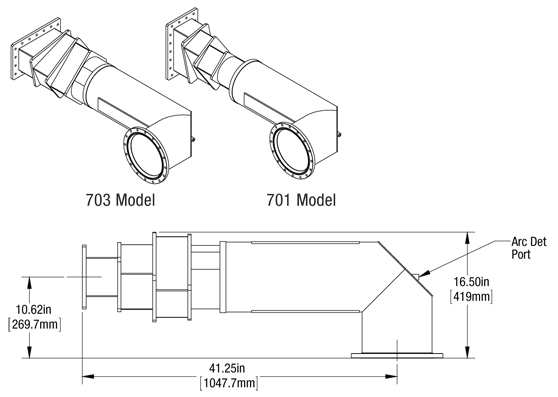

Microwave Feeds

Rely On MACHWAVE™ Technology for Bacon and Tempering Systems. Circular Polarized Feeds Decrease System Arcs While Improving Heating Uniformity!

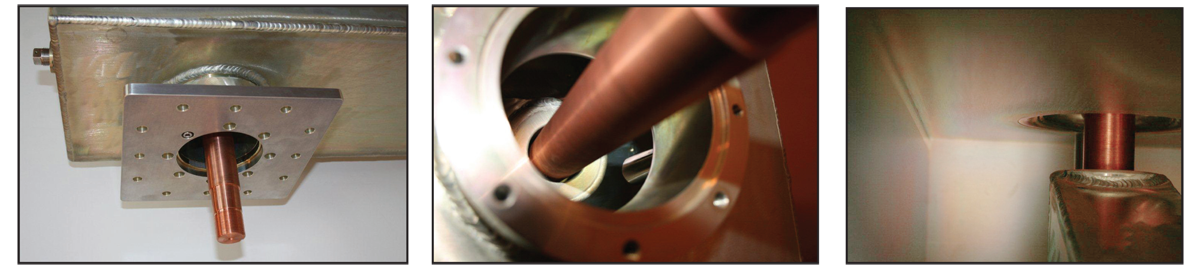

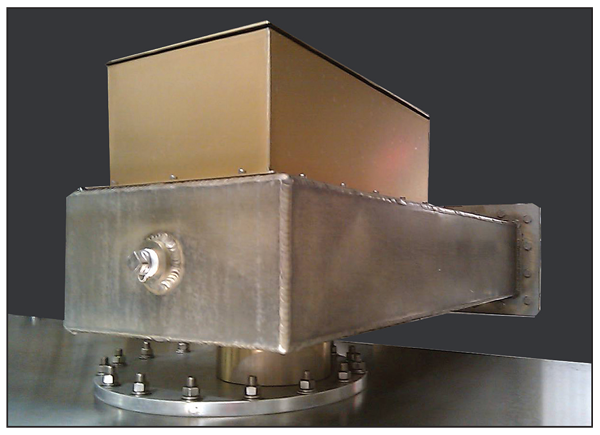

The MACHWAVE™ Polarized Feed is a refined circularly polarized high power microwave feed. Its design provides improved uniformity of the electrical fields by improving the overall microwave electrical characteristics of previous designs.

- It is not frequency dependent like competitors

- It has no moving parts like a rotary feed, but instead utilizes a phase changing electrical signal induced within the waveguide structure to rotate the energy

The rotation spins at the speed of the magnetron tube defined as 915 million times per second. Typical rectangular delivery systems have no rotational spin at all and "dump" the electrical energy directly into the cavity developing extremely high peak electrical fields.

Machwave's consistency eliminates the energy loss and uneven concentration of "peak electric field" found in all systems in operation today.

|